USA

USA

Latin America

Brazil & Portugal

888-800-2310 (Toll Free) 989-681-2158 (Local/International) 740 E Monroe Road, St. Louis, MI 48880

517-579-3061 Teléfono en México: 55-5351-3093 info@brinechlor.com

55-13-997855697

The P100 Sodium Hypochlorite Filter System is a precoated leaf filtration system designed to filter hypochlorite in batches of up to 40,000 liters. The filter is a manual process that requires an operator to precoat the plates at the start of the process and to remove the spent filtration media at the end of the batch. The total time required for precoating, filtration, and clean out of the system is approximately 5 hours for 40,000 liters. The P-100 has a footprint of 3.5m x 2.5m and is easily shipped in a standard shipping container.

The P100 can optionally be expanded to larger capacities to filter as much as 70,000 liter per batch.

All parts of the system are easily repaired and maintained. Typically, the filter is inspected every 6 to 9 months depending on the type of operation, and the filter cloth is replaced every 12 months with minimal expense.

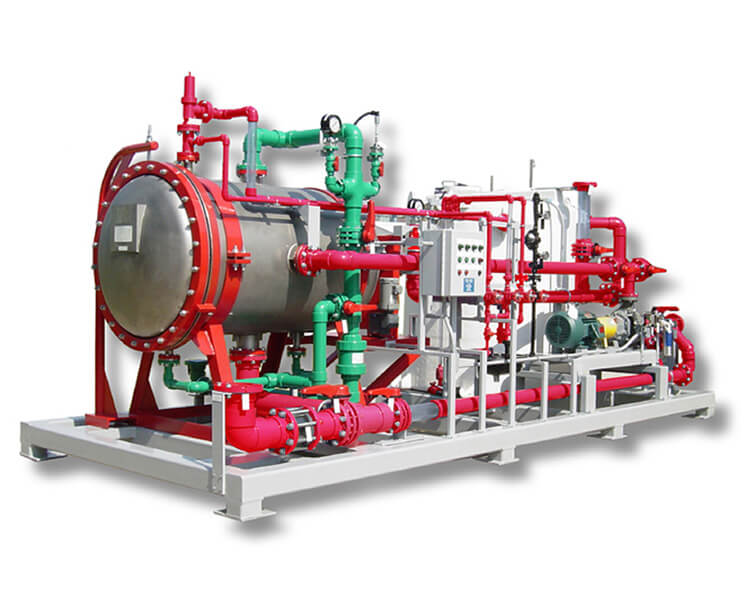

The Titanium Sodium Hypochlorite Filter System is a precoated leaf filtration system designed to filter hypochlorite in batches of up to 160,000 liters. The filter can be automated so that an operator is only needed for 20 minutes at the start of the process to precoat the plates and 5 minutes at the end of the process to wash the spent media from the system. The total time required for precoating, filtration, and clean out of the system is approximately 6 hours for 160,000 liters. The Titanium Sodium Hypochlorite Filter System has a footprint of 6.1m X 2.2m and can be shipped in a standard shipping container.

The Titanium Sodium Hypochlorite Filter System is available in 3 standard sizes of 100, 200, and 300 square feet of filtration area. Any of the systems can be ordered with reduced plates to allow for future expansion.

All parts of the system are easily repaired and maintained. Typically, the filter is inspected every 6 to 9 months depending on the type of operation, and the filter cloth is replaced every 12 months with minimal expense.