USA

USA

Latin America

Brazil & Portugal

888-800-2310 (Toll Free) 989-681-2158 (Local/International) 740 E Monroe Road, St. Louis, MI 48880

517-579-3061 Teléfono en México: 55-5351-3093 info@brinechlor.com

55-13-997855697

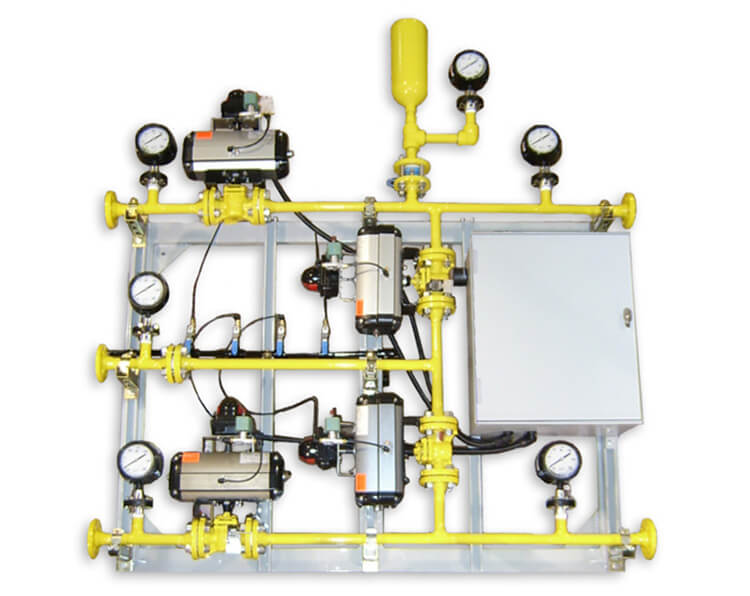

Our Sulfur Dioxide Transfer System is designed for the off-loading of sulfur dioxide from railcars or tank cars. The piping, valve arrangement, and program logic are based on the stringent safety standards used in the chlorine industry for the unloading of railcars (The Chlorine Institute Pamphlet 57).

The system is supplied as a complete unit with all controls and instrumentation pre-assembled, wired, and pressure tested. This simplifies installation significantly, potentially resulting in considerable savings in time and materials.

It is completely customizable to accommodate individual customer needs. The top line of the system is used for the sulfur dioxide coming from the railcar or tank car, while the middle line is used to evacuate the line of sulfur dioxide before disconnecting it from the car. This line is pulled into a Powell Scrubber. The bottom line of piping is for padding sulfur dioxide vapor supply to the railcar or tank car using the Air Treatment System.